Tech - Spokes

what spokes?

What spokes to use?

While it’s true you can get wheels with aluminum, titanium, or carbon spokes, the vast majority of quality wheels are made from stainless steel wire. I believe DT, Sapim, and Pillar all use 18/8 Sandvick wire—although each has their own special blend.

Spinergy have their own spokes PBO almost like a fiber/plastic look and Berd has develop their own polymer spokes that looks like a rope and lastly, we have seen the introduction of carbon spokes.

They are available in straight gauge, butted (multiple diameters) and bladed versions. Most quality spokes are either butted or bladed because they are lighter and stronger than straight gauge spokes. This additional strength is the result of forging the butted or bladed sections. The forging realigns the molecules to give them additional strength. The bladed spokes are typically stronger than the butted spokes because the blade is the result of an additional forging process over the butted spoke.

Despite claims to the contrary, J bend and straight pull spokes are pretty much the same strength and it’s the spoke count and gauge that determine stiffness. Spokes would normally break at the J bend, but those days are long gone with the introduction of triple butted spokes.

Point in case the Pillar TPB serries 2.2 at the J bend and better steel.

Scorpion Bike Wheels recommends for a durable wheel and easier service brass nipples.

The weight difference for a 24 spoke wheel its only 15g. per wheel.

Alloy nipples are available in color and work well for alloy rims in dry weather but with carbon rims you get "battery effect" and the nipples corrode badly causing the head to brake and they usually Sease to the spoke making it impossible, in most cases, to true the wheel.

I prefer to use 14mm nipples for MTB and 12mm for road but to save some weight 12mm for MTB work good as well.

Pillar wing bladed 4.3g

Sapim cxray bladed 4.25g

Pillar Megalite 3.2g

Berd 2.3g

Carbon bladed spokes 2.0g

While it’s true you can get wheels with aluminum, titanium, or carbon spokes, the vast majority of quality wheels are made from stainless steel wire. I believe DT, Sapim, and Pillar all use 18/8 Sandvick wire—although each has their own special blend.

Spinergy have their own spokes PBO almost like a fiber/plastic look and Berd has develop their own polymer spokes that looks like a rope and lastly, we have seen the introduction of carbon spokes.

They are available in straight gauge, butted (multiple diameters) and bladed versions. Most quality spokes are either butted or bladed because they are lighter and stronger than straight gauge spokes. This additional strength is the result of forging the butted or bladed sections. The forging realigns the molecules to give them additional strength. The bladed spokes are typically stronger than the butted spokes because the blade is the result of an additional forging process over the butted spoke.

Despite claims to the contrary, J bend and straight pull spokes are pretty much the same strength and it’s the spoke count and gauge that determine stiffness. Spokes would normally break at the J bend, but those days are long gone with the introduction of triple butted spokes.

Point in case the Pillar TPB serries 2.2 at the J bend and better steel.

Scorpion Bike Wheels recommends for a durable wheel and easier service brass nipples.

The weight difference for a 24 spoke wheel its only 15g. per wheel.

Alloy nipples are available in color and work well for alloy rims in dry weather but with carbon rims you get "battery effect" and the nipples corrode badly causing the head to brake and they usually Sease to the spoke making it impossible, in most cases, to true the wheel.

I prefer to use 14mm nipples for MTB and 12mm for road but to save some weight 12mm for MTB work good as well.

Pillar wing bladed 4.3g

Sapim cxray bladed 4.25g

Pillar Megalite 3.2g

Berd 2.3g

Carbon bladed spokes 2.0g

BERD, THE WORLD'S LIGHTEST SPOKES

BERD, THE WORLD'S LIGHTEST SPOKES

Welcome to the future of cycling. 2.3g

Berd have engineered an innovative bicycle spoke to bring your cycling to a new level. Berd PolyLight spokes leverage the latest advances in polymer technology to create the world’s lightest spoke while maintaining exceptional strength, aerodynamics, and durability.

Berd was founded in 2015 with a mission to use advancements in materials science and engineering to improve cycling products. Our PolyLight™ spokes are the lightest in the world. They enable cyclists to ride further and faster, while expending less effort.

Berd have engineered an innovative bicycle spoke to bring your cycling to a new level. Berd PolyLight spokes leverage the latest advances in polymer technology to create the world’s lightest spoke while maintaining exceptional strength, aerodynamics, and durability.

Berd was founded in 2015 with a mission to use advancements in materials science and engineering to improve cycling products. Our PolyLight™ spokes are the lightest in the world. They enable cyclists to ride further and faster, while expending less effort.

SAPIM, LEGENDARY BELGIUM TECHMOLOGY

SAPIM, LEGENDARY BELGIUM TECHMOLOGY

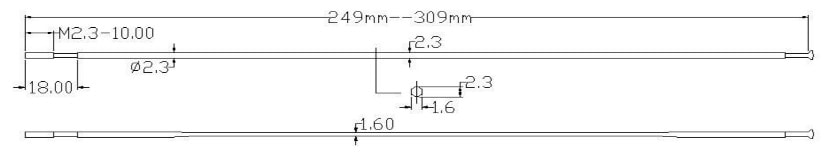

Most Polpular Spoke CXRAY 4.25g

(used by Zipp-Enve)

Founded in 1918 by Mr. Herman Schoonhoven, Sapim has been producing spokes and nipples of the highest quality for over a century! This is a significant milestone for which we are all very proud of.

Sapim would not have survived over 100 years if it didn’t rely on the best and most motivated people. We are a team of professionals dedicated to bicycle spokes and nipples. Everybody is committed to providing top-notch expertise, experience and advice to customers.

We constantly monitor each step of our production process. We offer a wide range of products made from the very best raw materials only. We call on the services of a unique testing facility to test the performance of our products and those of our customers, because wheels are subject to more and more intensive uses, higher pressures and stronger weight requirements. Today many professionals rely on Sapim products. It is without surprise that Sapim is considered by many professionals as the leader in the design and production of spokes and nipple.

(used by Zipp-Enve)

Founded in 1918 by Mr. Herman Schoonhoven, Sapim has been producing spokes and nipples of the highest quality for over a century! This is a significant milestone for which we are all very proud of.

Sapim would not have survived over 100 years if it didn’t rely on the best and most motivated people. We are a team of professionals dedicated to bicycle spokes and nipples. Everybody is committed to providing top-notch expertise, experience and advice to customers.

We constantly monitor each step of our production process. We offer a wide range of products made from the very best raw materials only. We call on the services of a unique testing facility to test the performance of our products and those of our customers, because wheels are subject to more and more intensive uses, higher pressures and stronger weight requirements. Today many professionals rely on Sapim products. It is without surprise that Sapim is considered by many professionals as the leader in the design and production of spokes and nipple.

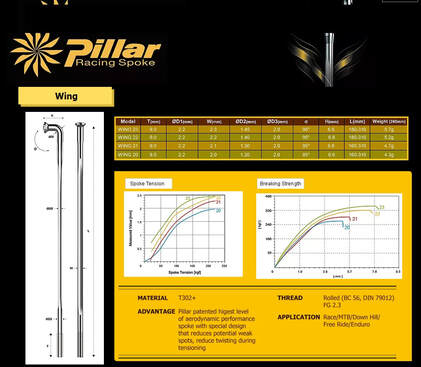

PILLAR, AFFORDABLE INNOVATION

PILLAR, AFFORDABLE INNOVATION

Introducing NEW Pillar Wing. 4.3g

For over 30 years, Pillar has been a world leader in the development of spokes. With specialized production facilities in Taiwan closely linked to its own research and development facilities, Pillar is today the first choice for spokes and nipples from the most renowned manufacturers in the bicycle industry.

Production is currently well over 1.5 million units per month.

Pillar holds countless patents on the technologies and products that have been developed over the years, and these reliably find their way to our customers all over the world through the spokes and nipples.

Continuous research and development in materials and processes will continue to ensure that Pillar continues to meet the highest standards in the industry.

For over 30 years, Pillar has been a world leader in the development of spokes. With specialized production facilities in Taiwan closely linked to its own research and development facilities, Pillar is today the first choice for spokes and nipples from the most renowned manufacturers in the bicycle industry.

Production is currently well over 1.5 million units per month.

Pillar holds countless patents on the technologies and products that have been developed over the years, and these reliably find their way to our customers all over the world through the spokes and nipples.

Continuous research and development in materials and processes will continue to ensure that Pillar continues to meet the highest standards in the industry.