Scorpion carbon Technologies

SCORPION CARBON RIMS: ARE MANUFACTURED WITH TORAY T700-T800-T1000

AUTO FILAMENT WINDING: PROCESS BY A ROBOT

PAINT-LESS TECHNOLOGY : CLEANER RIM FINISH OUT OF THE MOLD, LOWER WEIGHT AND SCRATCH RESISTANTE

AUTO FILAMENT WINDING: PROCESS BY A ROBOT

PAINT-LESS TECHNOLOGY : CLEANER RIM FINISH OUT OF THE MOLD, LOWER WEIGHT AND SCRATCH RESISTANTE

Hand crafted in USA

Designed by geek engineers tested in lab for strength and aero performance and tortured in the real word by bike fanatics

There has been a flood of new carbon clinchers into the market, with vastly differing levels of quality.

Our carbon rim brake utilize advanced technologies AFW (Auto Filament Wound) and our own patented heat resistant resin in the production that allows them to safely withstand the extreme heat (240c) and force created under different cycling condition, even the hard and long braking without any heat failure.

Auto Filament Wound Technology (AFW) has changed the way carbon rims are produced. Different than producing the rims by hand, Filament Winding is done by Robot, which is Pre-Coding with program, so human error is removed from the equation. That produces the stiffest and most durable laminated rim in the world. It is our laminate design along with our new patented TGH 240c resin, that gives an edge on the competition In trade this process cuts manufacturing labor time and thus cost.

We are confident that you will be satisfied with the performance and value of our products, or your money back. We back our products with 5 year warranty, and offer a discounted parts only charge on crash replacement.

FAQ:

Q: Do dimple rims work for aero gains ?

A: No. An online Reynolds number calculator with velocity = 12 m/s (43.2 kph) width of 24 mm, and kinematic viscosity of 1.5111E-5 m2/s at 20 Celsius. The Reynolds number is ~ 2*10^4; which at @15:54, means that wheels aren't even in the range when turbulent boundary layers matter for reducing drag coefficient. If you recalculated at 72 kph, (45mph) you only get 3*10^4. So there is no realistic speed regime this would matter.

- Conclusion, If you can ride at 45 mph for one hour you may save 3 seconds.

Did you know: if you move your hand to your face to adjust the sun glasses will cost you 3 watts, and it is exponential to speed.

-Ceramic Speed and Absolute Black over sized derailleurs pulleys save you 0.5-1 watt for a modest $700

Q: Do the wale style fins on the rim work to improve speed?

A: Yes, if you ride the bike on the bottom of the ocean

Q: When was it the last time you saw airplanes with dimples or wale fins on their wings!?

A: Don't you think NASA, Boeing and Airbus would implement it if it worked?

Q: Do dimple rims work for aero gains ?

A: No. An online Reynolds number calculator with velocity = 12 m/s (43.2 kph) width of 24 mm, and kinematic viscosity of 1.5111E-5 m2/s at 20 Celsius. The Reynolds number is ~ 2*10^4; which at @15:54, means that wheels aren't even in the range when turbulent boundary layers matter for reducing drag coefficient. If you recalculated at 72 kph, (45mph) you only get 3*10^4. So there is no realistic speed regime this would matter.

- Conclusion, If you can ride at 45 mph for one hour you may save 3 seconds.

Did you know: if you move your hand to your face to adjust the sun glasses will cost you 3 watts, and it is exponential to speed.

-Ceramic Speed and Absolute Black over sized derailleurs pulleys save you 0.5-1 watt for a modest $700

Q: Do the wale style fins on the rim work to improve speed?

A: Yes, if you ride the bike on the bottom of the ocean

Q: When was it the last time you saw airplanes with dimples or wale fins on their wings!?

A: Don't you think NASA, Boeing and Airbus would implement it if it worked?

Scorpion Carbon Rims

Crossbow Series introduced in 2018

Road Racing/Crit/climbing

Auto Filament Winding

3 cross filament pattern

Super light and stronger

Tubeless ready

Rim Brake:

26mm Wide x 38mm, 50mm Deep (28mm wide special order)

38mm-425g / 50mm-460g

Disc Brake :

28mm wide x 45mm deep

Aero Bladed Carbon Spokes

Weight 1350g

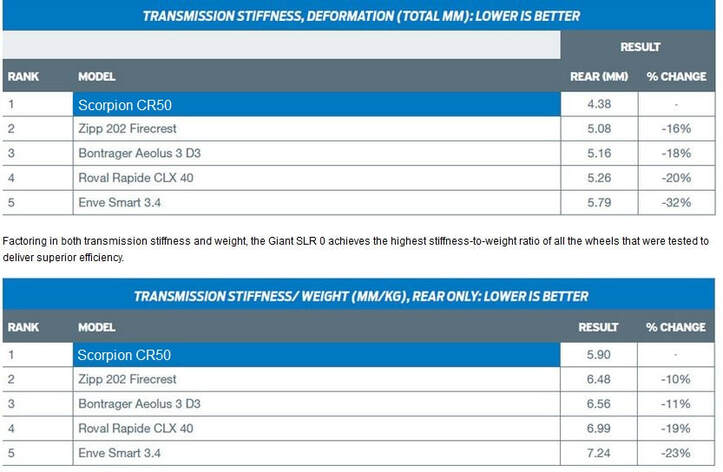

We introduced this rim in 2015, and It has been feature at GCN show.

The stiffest wheel they ever tested

Road Racing/Crit/climbing

Auto Filament Winding

3 cross filament pattern

Super light and stronger

Tubeless ready

Rim Brake:

26mm Wide x 38mm, 50mm Deep (28mm wide special order)

38mm-425g / 50mm-460g

Disc Brake :

28mm wide x 45mm deep

Aero Bladed Carbon Spokes

Weight 1350g

We introduced this rim in 2015, and It has been feature at GCN show.

The stiffest wheel they ever tested

Venom Series

This is our first Auto Filament Wound rim introduced in 2013

Road Racing/Crit/TT

Auto Filament Winding

UD Tangent wound

Tubeless/Clincher

Rim Brake: 26mm Wide x 36/ 50/ 60/80mm Deep

36mm-440g / 50mm-470g / 60mm-480g

Disc Brake: 28mm wide x 35/45/67mm deep

All Road Disc: 30mm wide x 40mm deep 460g.

Rim Brake or Disc

This is our first Auto Filament Wound rim introduced in 2013

Road Racing/Crit/TT

Auto Filament Winding

UD Tangent wound

Tubeless/Clincher

Rim Brake: 26mm Wide x 36/ 50/ 60/80mm Deep

36mm-440g / 50mm-470g / 60mm-480g

Disc Brake: 28mm wide x 35/45/67mm deep

All Road Disc: 30mm wide x 40mm deep 460g.

Rim Brake or Disc

Velocita Series

Endurance/TT

Prepeg T800 18k

Tubeless ready

Lazer cut brake track, Nanotech

Wider profile

Available 50mm, 60mm

Rim Brake

Endurance/TT

Prepeg T800 18k

Tubeless ready

Lazer cut brake track, Nanotech

Wider profile

Available 50mm, 60mm

Rim Brake

CROSSKING

Auto Filament wound

Cyclocross/Gravel

Disc Brake

Tubeless rim only

Asymmetry EQTM for stronger wheel

30mm Wide 35mm Deep

Tubeless disc only

Auto Filament wound

Cyclocross/Gravel

Disc Brake

Tubeless rim only

Asymmetry EQTM for stronger wheel

30mm Wide 35mm Deep

Tubeless disc only

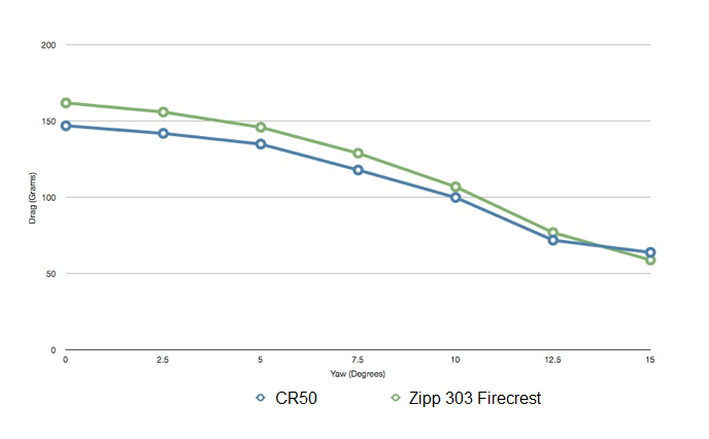

Scorpion Venom Series Carbon Rims Test Data

Venom CR50 Carbon Rim

Venom CR50 Carbon Rim

Venom - Carbon Rim Technology:

Carbon from Toray T800

Mitsubishi Rayon in Japan, the world’s largest producer of carbon fiber

– Used by the aeronautical and defense industries.

- Braking surface up to 240c deg.

- Composite, CNT (Carbon Nano Technology)

- 50-200 gpa (100 times of steel)

- EPS (Expanded Polystyrene System) keeps the inside smooth by melting away in the casting process.

Carbon from Toray T800

Mitsubishi Rayon in Japan, the world’s largest producer of carbon fiber

– Used by the aeronautical and defense industries.

- Braking surface up to 240c deg.

- Composite, CNT (Carbon Nano Technology)

- 50-200 gpa (100 times of steel)

- EPS (Expanded Polystyrene System) keeps the inside smooth by melting away in the casting process.

|

Venom Rim Specs

CR36-440g /CR50-470g/CR60-550g/CR80-650g ERD mm: 568/545/520/480 Rider weight limit: NO limit Max tire pressure: 125PSI Max spoke tension: 140KGF Flatness: ≤0.2mm Roundness: ≤0.3mm UCI / ISO test standard |

Carbon wheel rim brake test

Rim test failure at 20 mph with same brake pressure applied until rim explodes

(this is the reason why Big wheel companies are pressuring Big bike companies to go with disc brakes)

In the test bellow shows the time in seconds and temperature F of the rim before plodding

Notice that some rims got hotter as the time before failure went down.

We can assume that, more friction = better braking = more heat = quicker failure

Carbon is a non conductive material so, heat builds up. This is a problem because heat will not transfer throughout the entire rim surface but, it will remain on the applied area of friction, brake track. As the resin gets soft with the heat, the pressure from the tire forces the rim outward. Once the tire bid passes the edge of the rim, the tube explodes destroying everything on it's way.

Roval Wheels were the worst in this test, ouch. (pic #4)

(this is the reason why Big wheel companies are pressuring Big bike companies to go with disc brakes)

In the test bellow shows the time in seconds and temperature F of the rim before plodding

Notice that some rims got hotter as the time before failure went down.

We can assume that, more friction = better braking = more heat = quicker failure

Carbon is a non conductive material so, heat builds up. This is a problem because heat will not transfer throughout the entire rim surface but, it will remain on the applied area of friction, brake track. As the resin gets soft with the heat, the pressure from the tire forces the rim outward. Once the tire bid passes the edge of the rim, the tube explodes destroying everything on it's way.

Roval Wheels were the worst in this test, ouch. (pic #4)

How did we fair with our Scorpion Venom series rim?

Scorpion Venom rim - 1200s / 264f, cooled down to (0c) in just 34s - *0c=room temperature

Scorpion Venom rim - 1200s / 264f, cooled down to (0c) in just 34s - *0c=room temperature

Compare ENVE vs Scorpion Venom Series

(AFW) - Auto Filament Winding

The carbon filament comes in a spool and goes through the resin tank as it gets wrapped around a mold to form the rim, and its cut into shape by a mandrel. This creates a uniform rim without seams or deformation. The patented high temp resin is applied in the process.

A computer controlled robot controls the entire operation, assuring precision and uniformity.

NO HUMAN ERROR IN THE PROCESS

A computer controlled robot controls the entire operation, assuring precision and uniformity.

NO HUMAN ERROR IN THE PROCESS

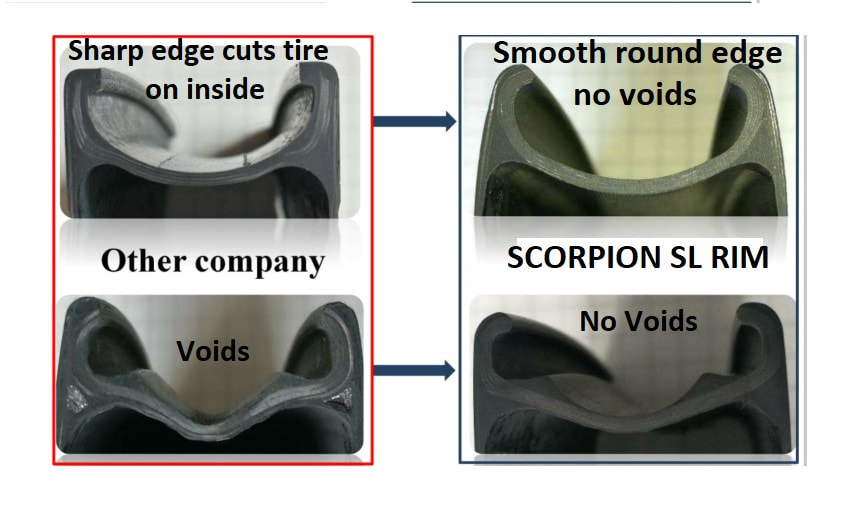

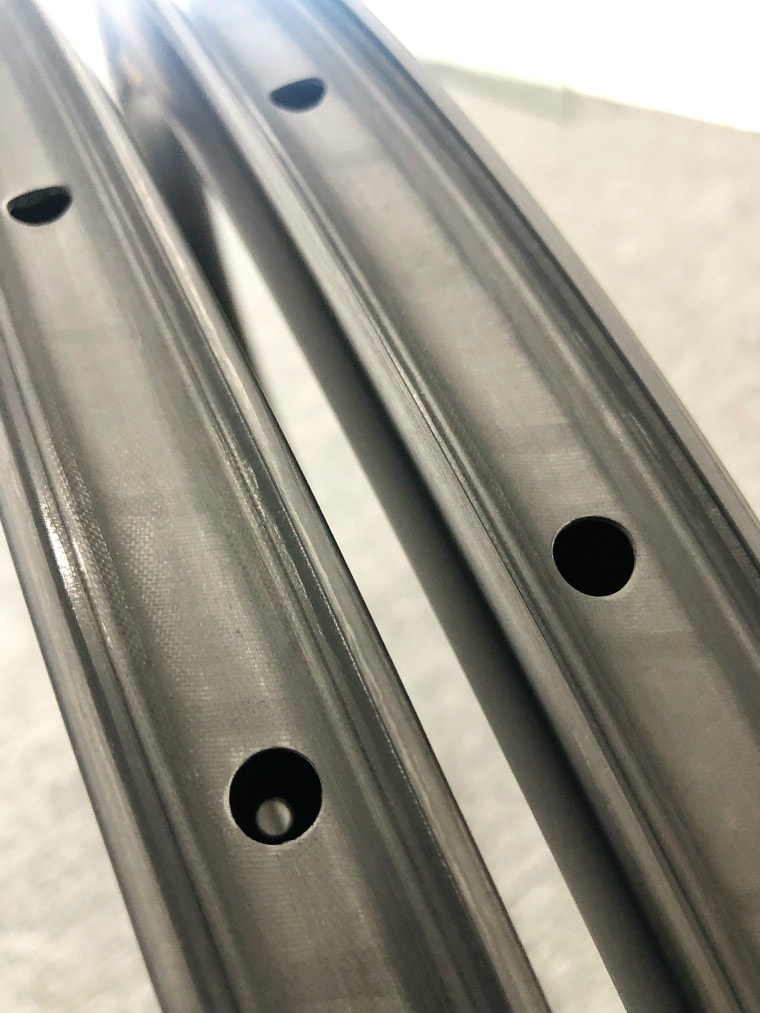

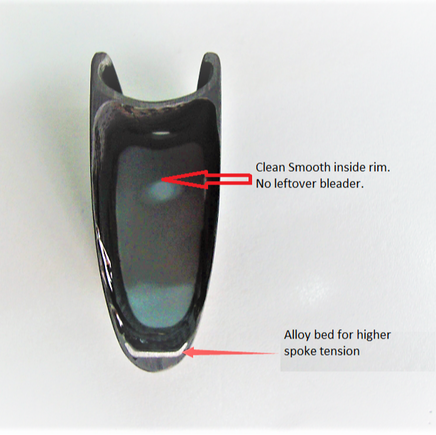

Scorpion rims - under the "hood"

Section Cut- looking inside

-Smooth interior wall

-Alloy belt, to reinforce nipple contact

With our filament winding system and EPS mandrel used by other big names like, ENVE the interior of the rim stays smooth. EPS was developed in Germany and its like a foam material that melts away after process.

Other rims use bladder system( a balloon) that will wrinkle and cause a uneven surface on the inside, and that in turn causes uneven weight distribution.

To Reinforce spoke nipple contact and spoke tension we added a alloy belt

Baking process:

One time high temp molding one time cool down and two times high temp baking

-Smooth interior wall

-Alloy belt, to reinforce nipple contact

With our filament winding system and EPS mandrel used by other big names like, ENVE the interior of the rim stays smooth. EPS was developed in Germany and its like a foam material that melts away after process.

Other rims use bladder system( a balloon) that will wrinkle and cause a uneven surface on the inside, and that in turn causes uneven weight distribution.

To Reinforce spoke nipple contact and spoke tension we added a alloy belt

Baking process:

One time high temp molding one time cool down and two times high temp baking

Venom CR50 rim test

Venom CR50 rim test

Venom Rim TGI brake test

We have the test machine in the factory to test the rims/wheels, the machine works by spinning a wheel using a chain and simulated rider load and then applying braking force while measuring temperature at multiple points hundreds of times a second using laser technology. The machine can also precisely measure wheel and tire width and see how these dimensions change as braking is applied and heat is generated.

We have the test machine in the factory to test the rims/wheels, the machine works by spinning a wheel using a chain and simulated rider load and then applying braking force while measuring temperature at multiple points hundreds of times a second using laser technology. The machine can also precisely measure wheel and tire width and see how these dimensions change as braking is applied and heat is generated.

Toray Carbon Fiber

Many small factories, they only purchase the finished carbon fiber, so they don't have much control of resin application. We have the carbon weaving machine in house to make the carbon material to our specs. Further more, our factory purchase the carbon filament directly from from Torayca Japan and Mitsubishi Ryon T700-T800-T1000 used in aeronautical and defense industries, helping us develop the best rim quality possible and cutting costs by producing it in house.

Many small factories, they only purchase the finished carbon fiber, so they don't have much control of resin application. We have the carbon weaving machine in house to make the carbon material to our specs. Further more, our factory purchase the carbon filament directly from from Torayca Japan and Mitsubishi Ryon T700-T800-T1000 used in aeronautical and defense industries, helping us develop the best rim quality possible and cutting costs by producing it in house.

Auto Filament Wind

Our engineers developed an automatic wrapping machine to shape the rim bed, so each carbon fiber layer can be evenly distributed and tightly bonded, enabling its strength to reach a maximum value and uniformity. Other wheel manufactures purchase the carbon in sheets, pre-peg, and they cut it and lay it over a mold.If you look up close the rim you can see the seams.

Our engineers developed an automatic wrapping machine to shape the rim bed, so each carbon fiber layer can be evenly distributed and tightly bonded, enabling its strength to reach a maximum value and uniformity. Other wheel manufactures purchase the carbon in sheets, pre-peg, and they cut it and lay it over a mold.If you look up close the rim you can see the seams.

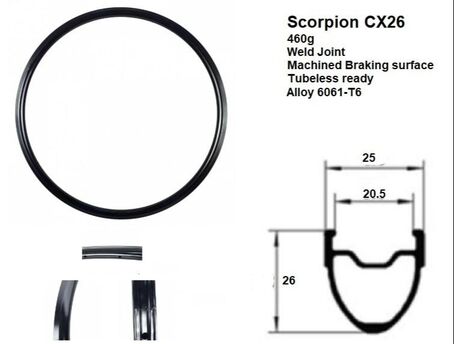

Scorpion Alloy Rims

We have two types of alloy rims

1) Our special developed tubeless ready rim CX26 is an all round performer used for most ride conditions.

Whether you go on road cross or gravel this rim at 470g is strong with extra material at the nipple edge so it can withstand higher spoke tensions and light enough to make a every day wheel of choice.

CX26 wheelset with 20/24 spokes weights in at 1500g. About the same as any big brand $900 wheel set.

2) For the more selected rider/racer we have SLR series rim made with, Super light Niobium alloy .

Niobium alloy is a proprietary material which has been developed by our rim supplier. Niobium alloy uses an advanced T10 heat-treatment process and delivers outstanding weight, stiffness and durability meaning rims can be wider for 25 and 28mm tires, deeper for better aero performance and yet remain super-light for excellent climbing and acceleration.

SLR series tubeless rims 24x26mm 440g / 24x31mm 480g.

1) Our special developed tubeless ready rim CX26 is an all round performer used for most ride conditions.

Whether you go on road cross or gravel this rim at 470g is strong with extra material at the nipple edge so it can withstand higher spoke tensions and light enough to make a every day wheel of choice.

CX26 wheelset with 20/24 spokes weights in at 1500g. About the same as any big brand $900 wheel set.

2) For the more selected rider/racer we have SLR series rim made with, Super light Niobium alloy .

Niobium alloy is a proprietary material which has been developed by our rim supplier. Niobium alloy uses an advanced T10 heat-treatment process and delivers outstanding weight, stiffness and durability meaning rims can be wider for 25 and 28mm tires, deeper for better aero performance and yet remain super-light for excellent climbing and acceleration.

SLR series tubeless rims 24x26mm 440g / 24x31mm 480g.

Scorpion CX Niobium Alloy series

Clincher/Tubeless ready

deep center channel for easier tire mount

6061-T6 Niobium alloy

Machined braking

Welded Rim

24mm widex 26mm deep

460-470g.

Clincher/Tubeless ready

deep center channel for easier tire mount

6061-T6 Niobium alloy

Machined braking

Welded Rim

24mm widex 26mm deep

460-470g.

SLR26 & CXD26

The all rounder rim that will perform under any ride styles. Available in rim or disc brake

With tubeless ready and a wide section it will excel on the Tarmac or gravel roads and the aero profile keeps you rolling on the flats.

Expect complete wheel-set at 1580g with our RS390 hubs and Sapim Race spokes

Custom decal color options available

The all rounder rim that will perform under any ride styles. Available in rim or disc brake

With tubeless ready and a wide section it will excel on the Tarmac or gravel roads and the aero profile keeps you rolling on the flats.

Expect complete wheel-set at 1580g with our RS390 hubs and Sapim Race spokes

Custom decal color options available

Scorpion SLR31

Scorpion SLR31

Scorpion SLR31

Aero Tubeless/Clincher

Niobium Alloy

24mm wide 31mm deep

480g. (as much as a 50 carbon rim)

Excellent rim for a classic build with aero profile

Great for you TT bike or road racing.

The deep section 31mm and 24mm wide makes its perfect for today's wider tire applications and you get a great aero look and performance.

Expect a complete wheel-set with our SL210 hubs to be at respectful 1500g.

Aero Tubeless/Clincher

Niobium Alloy

24mm wide 31mm deep

480g. (as much as a 50 carbon rim)

Excellent rim for a classic build with aero profile

Great for you TT bike or road racing.

The deep section 31mm and 24mm wide makes its perfect for today's wider tire applications and you get a great aero look and performance.

Expect a complete wheel-set with our SL210 hubs to be at respectful 1500g.